During the production phase, the cylinder is copper-plated by means of electrolysis and then immediately conveyed to the copper polishing machines, where the final dimensions are given based on the client’s instructions and the final finishing of the surface is performed.

Following selection of the correct specifications based on the requirements of the proof and the colour corresponding to each cylinder, the cylinder is engraved using our Hell, Ohio και Daetwyler engraving machinery.

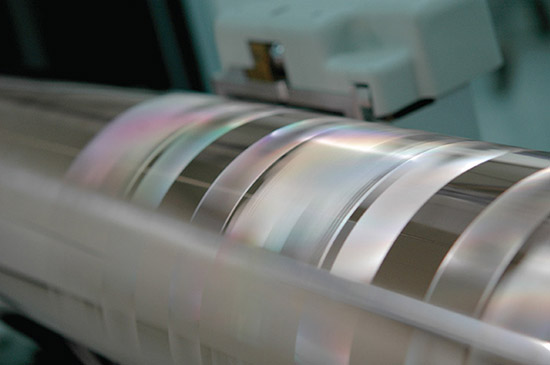

After the cylinder is engraved, the cylinder is conveyed to the chrome-plating machines and then the finishing machines so that degree of surface roughness can be specified according the client’s requirements.

The last stage is the printing of the cylinder proof in order to check that the digital proof approved by the client has been properly printed on the flexible packaging material selected. One of PRISMA’s advantages is the accurate matching of the digital proof to the cylinder proof.